Osmosis occurs in living organisms in which there is a piece of tissue or a membrane with fluids on either side of it. Fluids having a lesser concentration will be drawn through the tissue/membrane to mix with fluids having a greater concentration. This is to equalize the concentration of substances in the fluids on both sides of the tissue/membrane. This can be illustrated if you cut open an avocado, and salt the surface of one half. In a short time, you will notice water has been drawn out of the avocado to try to equalize the concentration of salt placed on the surface of the avocado. Osmosis occurs when there are two fluids of differing concentration separated by a semi-permeable membrane. The fluid will pass through the membrane in the direction of the most concentrated solution. Osmosis is the process through which oxygen will go from our lungs into the blood stream, and water and nutrients will penetrate the root structure of a tree enabling it to grow. When we quench our thirst with water, a quantity is placed in our stomach. This water will be diffused into our system to replenish what is lost as the life processes proceed. In the natural world surrounding us, and inside of us, there is a vast network of biological membranes. These screening barriers govern the selection and passage of chemicals and fluids.

Ultra filtration (UF) is a variety of membrane filtration in which hydrostatic pressure forces a liquid against a semi permeable membrane. Suspended solids and solutes of high molecular weight are retained, while water and low molecular weight solutes pass through the membrane. This separation process is used in industry and research for purifying and concentrating macromolecular (103 - 106 Da) solutions, especially protein solutions. Ultra filtration is not fundamentally different from microfiltration, nanofiltration or gas separation, except in terms of the size of the molecules it retains. Ultra filtration is applied in cross-flow or dead-end mode and separation in ultra filtration undergoes concentration polarization.

Process:

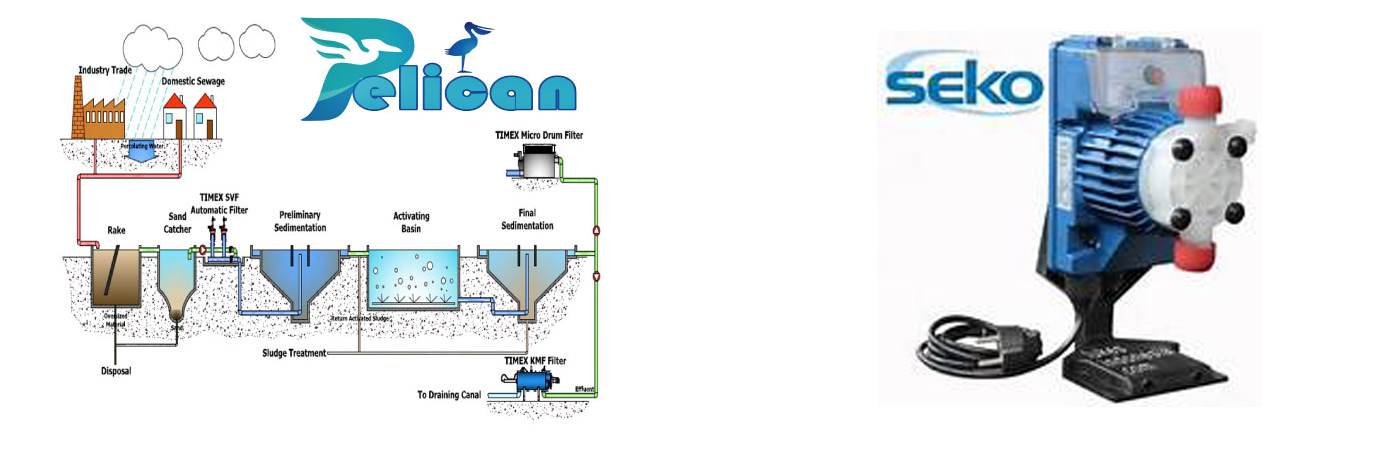

Ultra filtration systems eliminate the need for clarifiers and multimedia filters for waste streams to meet critical discharge criteria or to be further processed by wastewater recovery systems for water recovery. Efficient ultra filtration systems utilize membranes which can be submerged, back-flushable, air scoured, spiral wound UF/MF membrane that offers superior performance for the clarification of wastewater and process water.

Spiral wound module:

Consists of large consecutive layers of membrane and support material rolled up around a tube. Maximizes surface area.Less expensive, however, more sensitive to pollution.

Tubular membrane:

The feed solution flows through the membrane core and the permeate is collected in the tubular housing. Generally used for viscous or bad quality fluids. System is not very compact and has a high cost per unit area installed

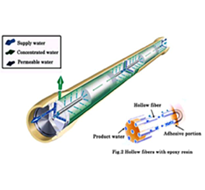

Hollow fiber membrane:

The modules contain several small (0.6 to 2 mm diameter) tubes or fibers. The feed solution flows through the open cores of the fibers and the permeate is collected in the cartridge area surrounding the fibers.The filtration can be carried out either “inside-out” or “outside-in”

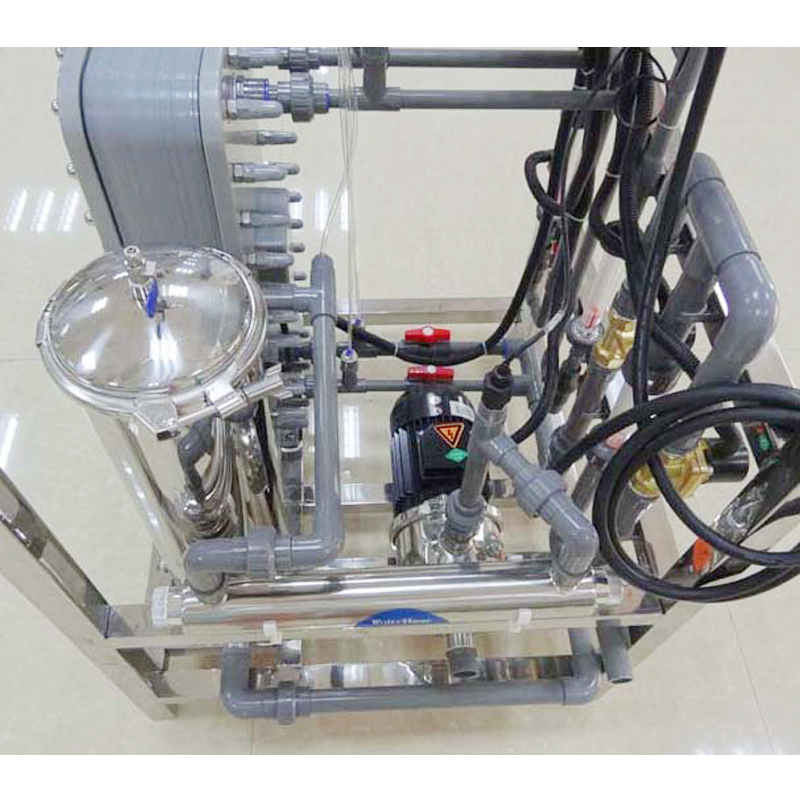

Pressurized system or pressure-vessel configuration:

TMP (trans membrane pressure) is generated in the feed by a pump, while the permeate stays at atmospheric pressure.Pressure-vessels are generally standardized, allowing the design of membrane systems to proceed independently of the characteristics of specific membrane elements.

Immersed system:

Membranes are suspended in basins containing the feed and open to the atmosphere. Pressure on the influent side is limited to the pressure provided by the feed column.TMP is generated by a pump that develops suction on the permeate side.Ultra filtration, like other filtration methods can be run as a continuous or batch process.

1. Particulate matter, turbidity, sediment, etc.

2. Colloidal matter.

3. Total dissolved solids (up to 99%).

4. Toxic metals.

5. Radium 226/228

6. Microorganisms (potable water only)

7. Asbestos.

8. Pesticides and herbicides (coupled with AC).

1. Dialysis and other blood treatments

2. Concentration of milk before making cheese

3. Downstream processing (e.g., concentration) of biotechnology-derived proteins (e.g., therapeutic antibodies)

4. Desalting and solvent-exchange of proteins (via diafiltration)

5. Fractionation of proteins

6. Clarification of fruit juice

7. Recovery of vaccines and antibiotics from fermentation broth

8. Laboratory grade water purification

9. Industrial wastewater treatment

10. Drinking water disinfection (including removal of viruses)

11. Removal of endocrines and pesticides combined with Suspended Activated Carbon pretreatment